Thread Sealing: Seal threaded and pipe connections reliably and leak-free

Prevent gas and liquid leakage

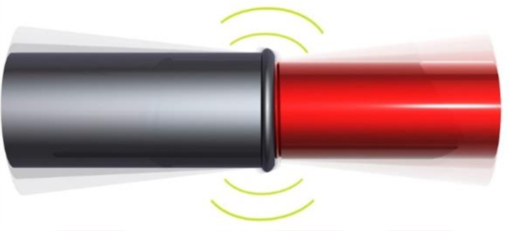

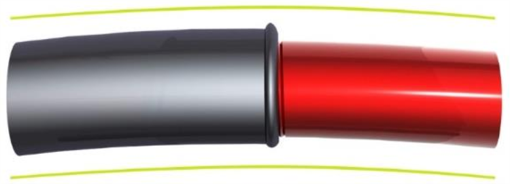

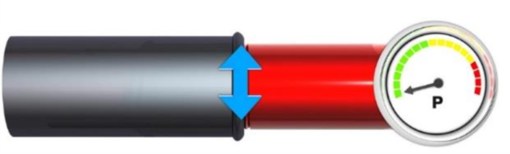

When threads or pipes are not properly connected, leaks can occur, allowing gases and liquids to escape. Thread Sealant fills the thread clearance and conforms to surface irregularities. Applying the sealant creates a barrier between the components and protects against vibration and shock. A liquid threadlocker also prevents corrosion in the thread and does not tend to shrink or warp.

What stresses can a thread withstand?

Threads have to withstand a variety of stresses. From vibration to temperature changes, from bending to pressure changes.

The Optimal Thread Sealant

Choosing the right thread sealant depends on your thread material, thread size, and the media being sealed. We offer several product types to meet these needs.

Liquid, Anaerobic or Thread Sealant?

Find the right technology:

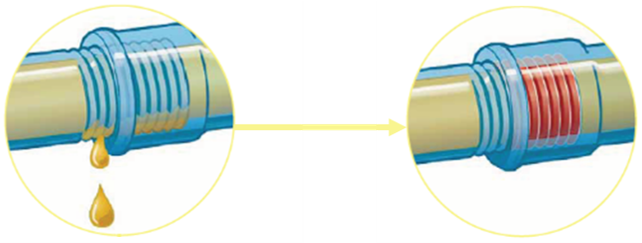

- Metal Fittings: Thread Sealant: Anaerobic thread sealant The contact of metal and air between the individual threads causes the compound to cure on the pipe joint.

- Pure plastic or plastic/metal combinations: Thread seal: Silicone sealant The sealant cures at room temperature by reaction with moisture.

- Tapered metal or plastic threads: Thread seal: This is a non-hardening, coated multifilament thread that seals the thread against water, gas, and most industrial oils.

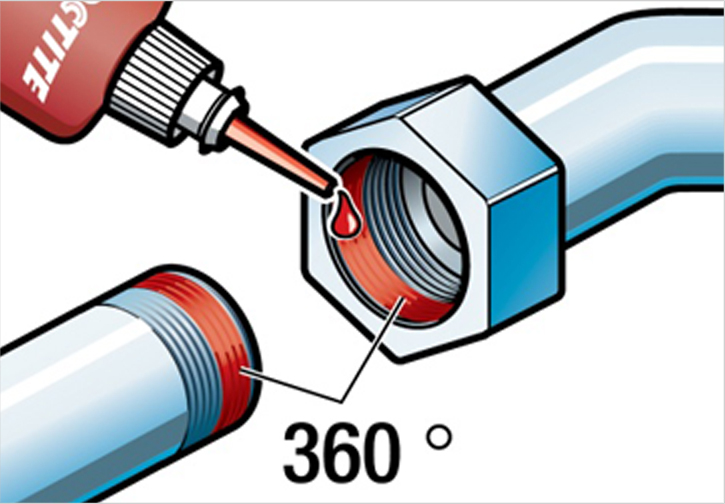

Applying Liquid Sealants

- Surface Preparation Thoroughly clean the joint:

- Degrease, clean and allow to dry.

- LOCTITE® SF 7063™ is a residue-free universal cleaner that is ideal for surface preparation.

- Apply the anaerobic seal to the male thread of the fitting. Note that an activator such as LOCTITE® SF 7649™ is required for pretreatment at temperatures below 5°C! It is also important to note that in the case of poorly cut or oversized threads, a sealant should be applied to both the male and female threads. LOCTITE® 577™ is a medium strength threadlocker suitable for metal assemblies.

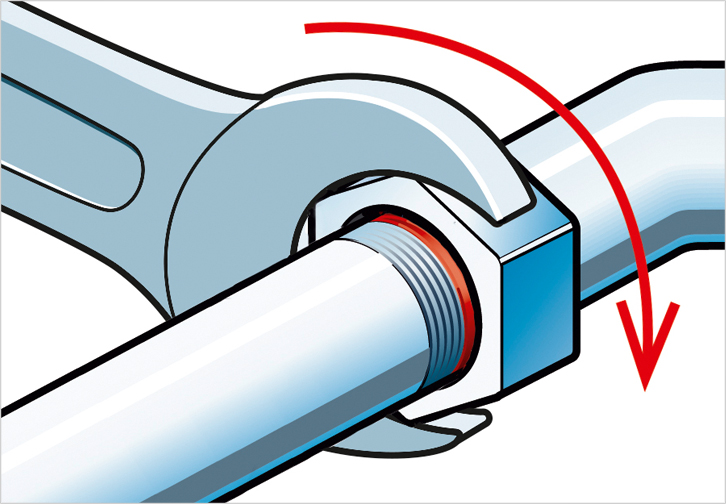

- Tighten the thread using an appropriate tool. A double-ended wrench is often sufficient to tighten the joint sufficiently.

Henkel

LOCTITE® 577™ medium strength thread sealant

The all-round product; universally applicable liquid thread sealant for sealing metallic threads.immediate sealing effect against low pressuresresistant to gasoline, oil, coolants and hydraulic fluidsP1 NSF Reg. No.: 123001DVGW approval (EN 751-1): NG-5146AR0621WRAS approval (BS 6920): 0711506

Sealing Threads: Sealing Threaded Sleeves and Fittings

- Surface Treatment: Grind thread with saw blade or file

- Refer to the label for the recommended amount of sealant for your thread size.

- Application: Apply the end of the sealant thread approximately two thread turns from the end of the male thread and hold it in place with a finger. Beginning at the end of the pipe, wrap the cord across the pipe thread in the direction of the thread. For optimum performance, the thread base should be filled without completely covering the sides of the pipe winding. NOTE: It is not necessary to place the sealant directly into the threads.

- Position the counter piece and tighten the joint with an appropriate tool. If necessary, the joint can be adjusted up to 45° without risk of leakage.

Accessories to ensure a perfect fit

The hand pump can be easily screwed onto any 50 ml Loctite® bottle.- converts product container into mobile dispensing device- nozzle can accommodate a variety of dispensing needles- application for Loctite® anaerobic threadlockers, joining adhesives and thread sealants